- 5G campus pilot factory „smartfactory@tugraz“ enables cooperative academic work and offers research service to develop forward-looking production processes

- With the 5G campus solution, Magenta Telekom supports agile, connected, and data-proof information processes in industry

- Ericsson is Magenta Telekom’s strategic partner delivering the 5G campus network infrastructure and associated services

- Innovation partner T-Systems develops use cases for practical applications

- Making innovation tangible: TU Graz presents 5G industry showcase with augmented reality and smart object recognition

Industry 4.0 is the Internet of Things for production and connects the entire value chain – machines, products, people and IT systems – to enable the broadest possible basis of automated and digitalized processes. For companies, this makes production more transparent, agile, efficient and cost-effective. For a year now, SMEs and large companies have been able to come to the unique pilot factory at Graz University of Technology (TU Graz), smartfactory@tugraz, to find out about and try out agile and data-proof production concepts using a wide range of disruptive technologies. Because this is where TU Graz is putting the production of the future into practice. The 300 square meter factory has a 5G campus network provided by Magenta Telekom. This enables fast, secure and high-volume data transfer specifically between all 5G-capable applications and devices.

The infrastructure of this research and learning factory at TU Graz includes many aspects necessary for forward-looking digital production concepts and technologies. In addition to the 5G campus network provided by Magenta Telekom, Ericsson provides the 5G hardware for smartfactory@tugraz as network producer and supplier. The initial industrial use cases from innovation partner T-Systems make the research and development work in production tangible.

“At the heart of our research interests is the design of production processes that are as agile and data-proof as possible,” said Rudolf Pichler, Head of smartfactory@tugraz, outlining the key areas. The 5G network could have a big impact here and the learning and research factory also acts as a valuable incubator for new applications in this regard. “As such, our research and learning factory is an important center for industry – especially for SMEs – who need more support in setting up Industry 4.0 infrastructure,” said Franz Haas, Director of the Institute of Production Engineering, underlining the importance of the learning and research factory. “Pilot factories are the ideal training ground for students, but also the ideal hub for all interested parties to share knowledge. Research and development can take place without disrupting operating processes.”

Werner Kraus, CCO Magenta Business: “These days, individual production and logistics units are already digitalized to a high degree. In order to increase automation and integratively network all components for the purpose of overall optimization, high-performance, secure infrastructure is needed. Conventional solutions like Wi-Fi are not sufficient for this. The 5G campus solution provided by Magenta enables all processes and systems to be connected flexibly in an autonomous, private 5G network – offering the best possible framework for the future of production. In actual fact, it was the needs of industry that led to the development of campus networks. We are delighted to be playing a part as digital partner to TU Graz and domestic industry, providing a campus solution.”

Pioneering work in the introduction of 5G technology for industry

Dedicated mobile networks that run on 5G technology enable companies to expand their capabilities and adapt dynamically to changing market requirements and to ensure that business processes are constantly optimized. Industry can benefit from innovative applications such as sensor technology, driverless transport vehicles (Automated Guided Vehicles – AGVs), drones, heavy machinery automation, or the development of robotics, for which 5G campus networks are essential. The Ericsson 5G campus portfolio enables network operators to grow beyond mobile broadband.

“We are delighted to be working with three such innovative partners as Magenta Telekom, T-Systems and Graz University of Technology, to together drive forward 5G and be part of setting up the first 5G campus network to the benefit of Austrian industry. At Ericsson, we work tirelessly to ensure that our innovations make use of all the benefits of connectivity to help various industries and the economy grow. This collaboration demonstrates the unique capabilities of wireless solutions and the high degree of reliability and information security that they offer. Mobile private networks provide enormous potential for tapping into further opportunities of digitalization in Austria. We are proud that this end-to-end approach has highlighted the full benefits of 5G campus networks for companies,” said Alexander Sysoev, Head of Ericsson Austria.

Innovation through collaboration

In the collaboration with smartfactory@tugraz, T-Systems brings to the table its expertise in the field of information security in an Industry 4.0 environment, with a focus on aspects relevant for cyber security and attack detection in IT and OT. It also contributes in the area of data handling, where, with the help of a data bus (PDM WebConnector), it ensures the controlled, end-to-end exchange of product data between engineering and order management, right through to production management and beyond.

“Without PDM WebConnector, the smart factory in Graz would just be a pipe dream: it connects the various management systems and resources with each other, like machines and systems in production, and ensures smooth data communication along the entire production chain, thus providing a kind of Esperanto – a language that can be understood by all systems involved in the process. Given the profound change that production is currently undergoing, the issue of innovation through collaboration is particularly important and valuable for T-Systems right now, especially in this area,” said Vincent Maholetti, Senior Expert Sales Digital Solutions at T-Systems in Austria.

The first case studies in production are also being developed, such as forward-looking maintenance and operation with the use of machine learning. T-Systems is also responsible for security at smartfactory@tugraz, including a firewall concept and intrusion detection for IT and OT.

Right in the thick of it, not just on the sidelines: amazing showcases

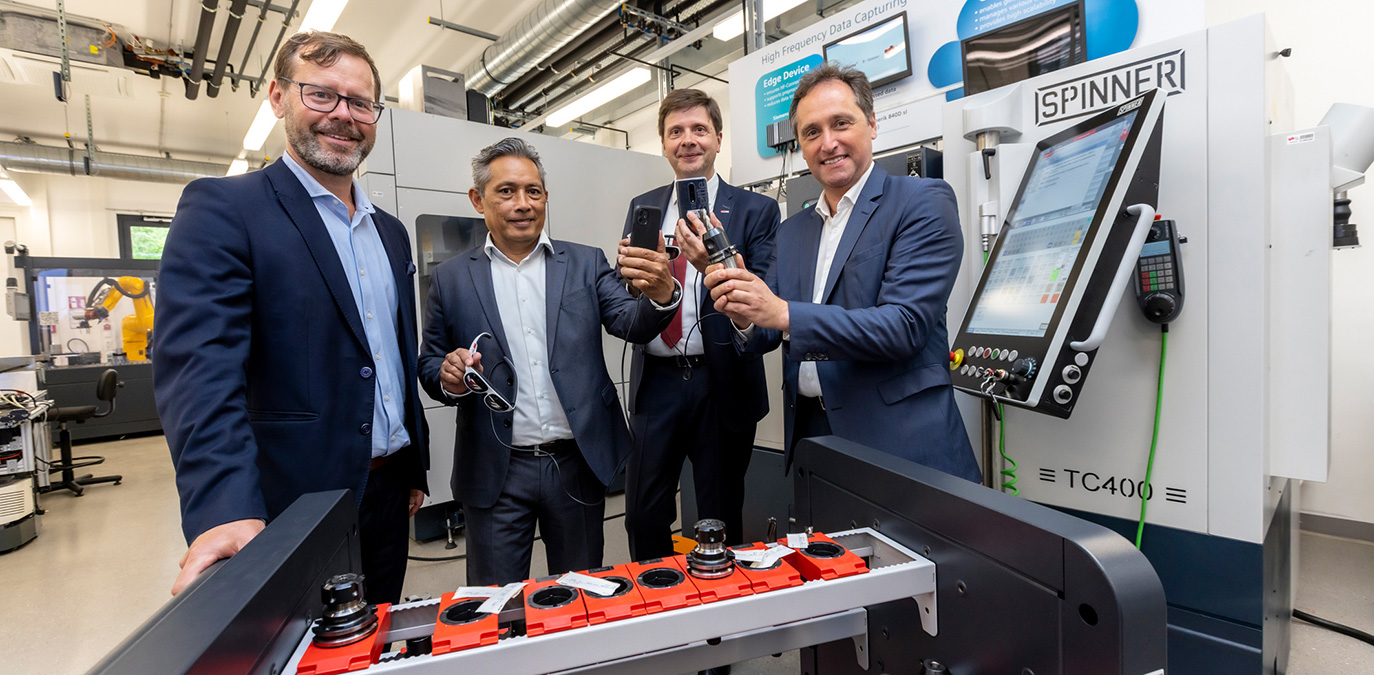

For the first anniversary, there were two innovative applications to experience live: how augmented reality using smart glasses is being deployed in the manufacturing industry and smart object recognition in production.

• Augmented reality (AR) with lightweight glasses and 5G connection

With conventional AR applications, the requisite computing power is built into the glasses, making them relatively heavy. The showcase uses lightweight glasses that are connected to a 5G-capable smartphone. The visual computing takes place on the usual high-performance computers, which connect wirelessly to the AR glasses via high-performance 5G infrastructure. Relocating the computing in this way makes the glasses lighter, without compromising on performance.

• Object recognition of a tool using AI

The fast and secure recognition of objects such as tools or products is crucial in production. In the showcase, the camera of a smartphone onto which a special app has been downloaded is pointed at the real object. The app sends the recorded image to an Azure cloud backend, where the object is identified using a specially trained AI algorithm and the object’s ID is shown on the smartphone. For workers, this is a simple and valuable way to check required information in the field.

Magenta Telekom

(T-Mobile Austria GmbH)

E-mail presse@magenta.at